When your boiler stops working unexpectedly, the immediate concern is restoring hot water and heating to your home as quickly as possible. While a non-functioning boiler can feel like an emergency, many common issues have simple solutions you can try before calling a heating engineer. Understanding the basic troubleshooting steps not only saves time and money but also helps you communicate more effectively with professionals when their expertise becomes necessary.

- First Safety Checks

Before attempting any troubleshooting when your boiler stops working, prioritizing safety protects you and your family from potentially dangerous situations involving gas appliances.

Switching Off and Inspecting Safely

Start by turning off your boiler at the main controls and switching off the power supply at your fuse box or circuit breaker. Check around the boiler area for any obvious signs of water leaks, unusual smells, or visible damage to pipes and connections. Never touch electrical components with wet hands, and ensure the area around your gas appliance is well-ventilated before proceeding with any checks.

Warning Signs of Serious Faults

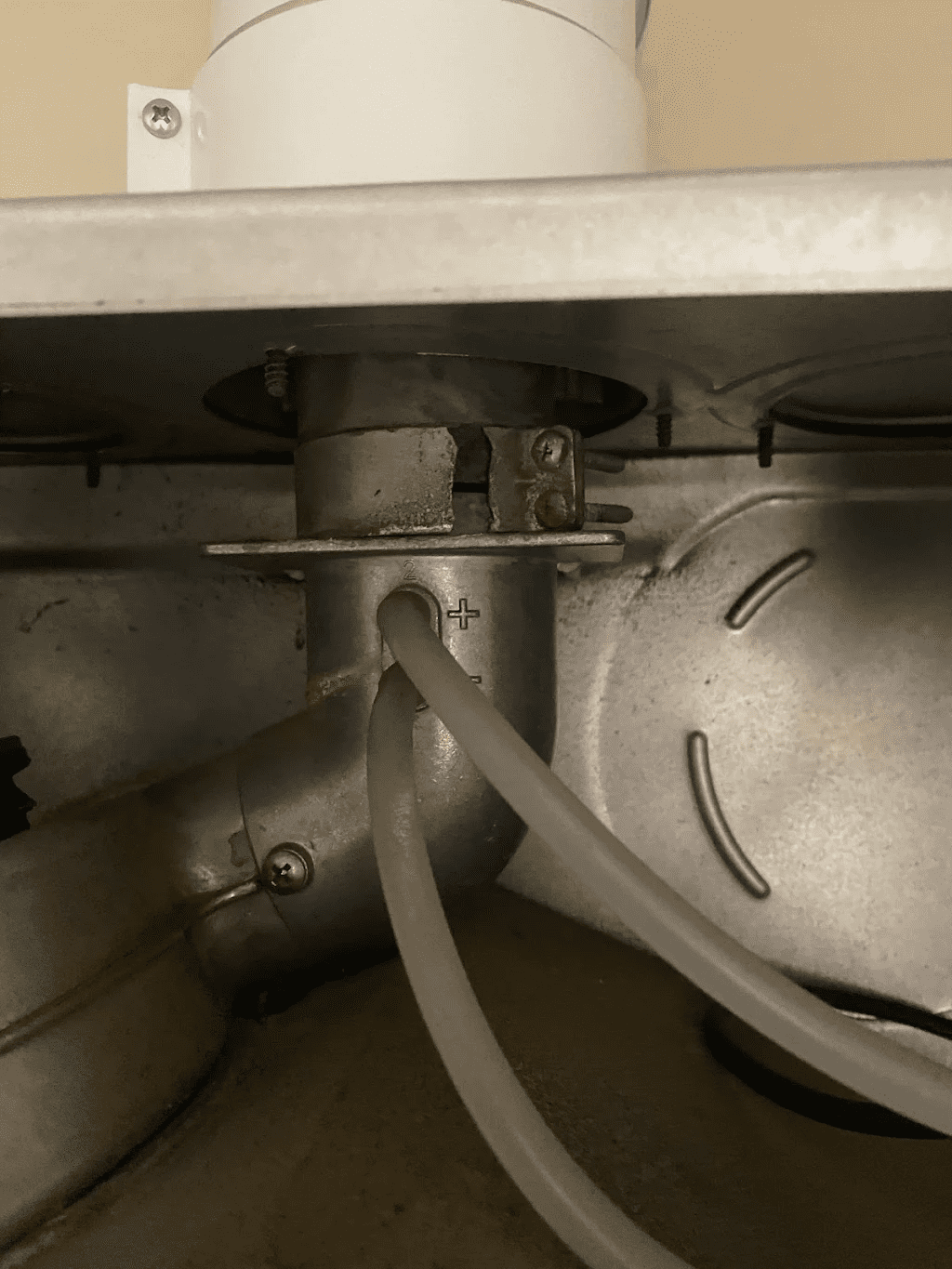

Certain symptoms indicate serious problems requiring immediate professional attention from a Gas Safe registered engineer. If you smell gas, hear unusual hissing sounds, or notice yellow flames instead of blue from the pilot light, evacuate the area immediately and contact emergency gas services. Black soot marks around the boiler, persistent error codes on digital displays, or signs of carbon monoxide exposure (headaches, dizziness, nausea) require urgent professional assessment.

These safety checks form the foundation for all subsequent troubleshooting steps and help determine whether DIY solutions are appropriate or professional intervention is necessary.

- Check the Power Supply

Electrical issues frequently cause boilers to stop functioning, making power supply verification an essential first troubleshooting step.

Resetting the Boiler

Modern boilers often feature reset buttons or switches that can restore operation after minor electrical disruptions or power cuts. Locate your boiler’s reset button, typically marked clearly on the control panel, and press it firmly for several seconds.

Wait at least five minutes before attempting to restart the system, allowing internal components to reset properly. Check your boiler controls display for any persistent error codes that might indicate specific problems requiring professional attention.

Ensuring Electricity and Gas Supply

Verify that your circuit breaker or fuse hasn’t tripped in your fuse box – boiler circuits sometimes share connections with other high-power appliances. Test other electrical appliances in the same area to confirm power availability. For gas supply verification, check whether other gas appliances like your cooker are working normally. Smart thermostat systems may lose connection during power disruptions, requiring reconnection to your home’s Wi-Fi network.

If power and gas supplies are functioning correctly but your boiler stops working after reset attempts, the problem likely lies within the boiler’s internal systems.

- Inspect the Thermostat and Controls

Thermostat malfunctions account for numerous heating system failures, often creating the impression that your boiler stops working when the issue lies with control systems.

Common Thermostat Issues

Battery-powered thermostats frequently stop working when batteries run low, preventing communication with your boiler system. Incorrect temperature settings, scheduling conflicts, or wireless connection problems with smart thermostat systems can interrupt heating cycles. Older mechanical thermostats may suffer from dust accumulation or calibration drift, causing inaccurate temperature readings that prevent proper boiler activation.

How to Adjust or Reset Controls

Replace thermostat batteries and verify that temperature settings exceed current room temperature by at least 2-3 degrees. Check programming schedules on digital models – many systems default to energy-saving modes that might appear as malfunctions. For smart thermostat installations, ensure Wi-Fi connectivity and app synchronization are functioning correctly. Reset wireless thermostats by following manufacturer instructions, typically involving holding specific button combinations for prescribed durations.

Examine your boiler controls directly – some systems have dual control points that must align properly for normal operation. The diverter valve position affects whether you receive heating, hot water, or both services from your system.

- Check Boiler Pressure

Water pressure problems represent one of the most frequent reasons why boiler stops working, yet they’re often easily resolved with basic maintenance procedures.

Signs of Low or High Pressure

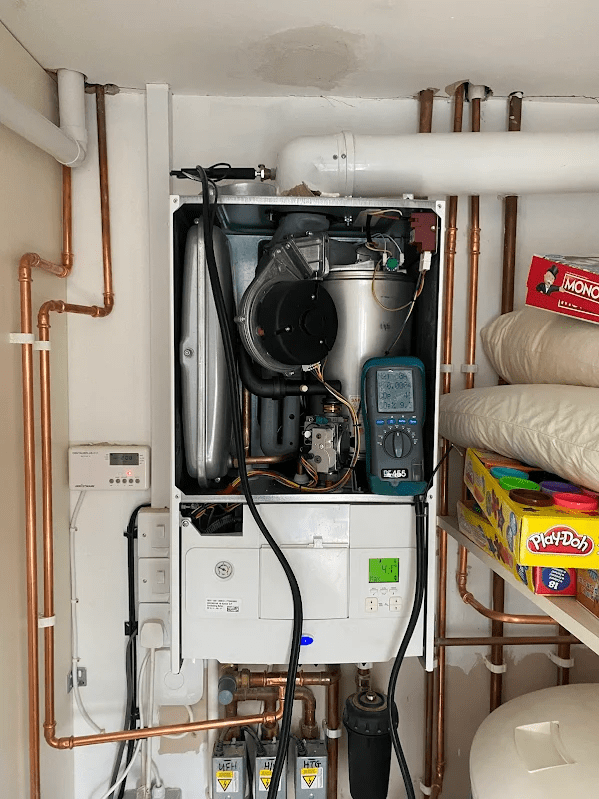

Your pressure gauge should typically read between 1 and 2 bar when the system is cold – readings below 1 bar indicate insufficient pressure for proper operation. Symptoms of low pressure include cold radiators, reduced hot water flow, or complete heating system failure. Conversely, pressure readings above 3 bar suggest over-pressurization, which can trigger safety shutdowns and potentially damage system components like the heat exchanger.

How to Repressurize Safely

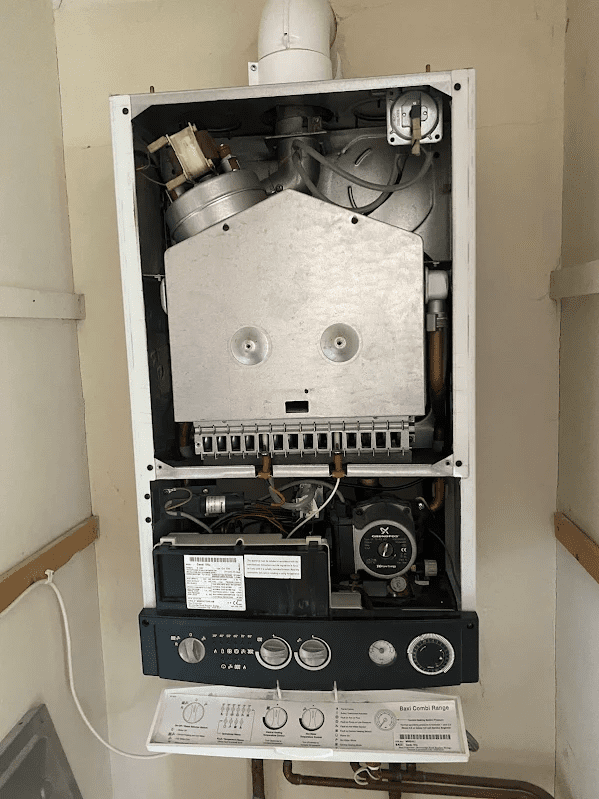

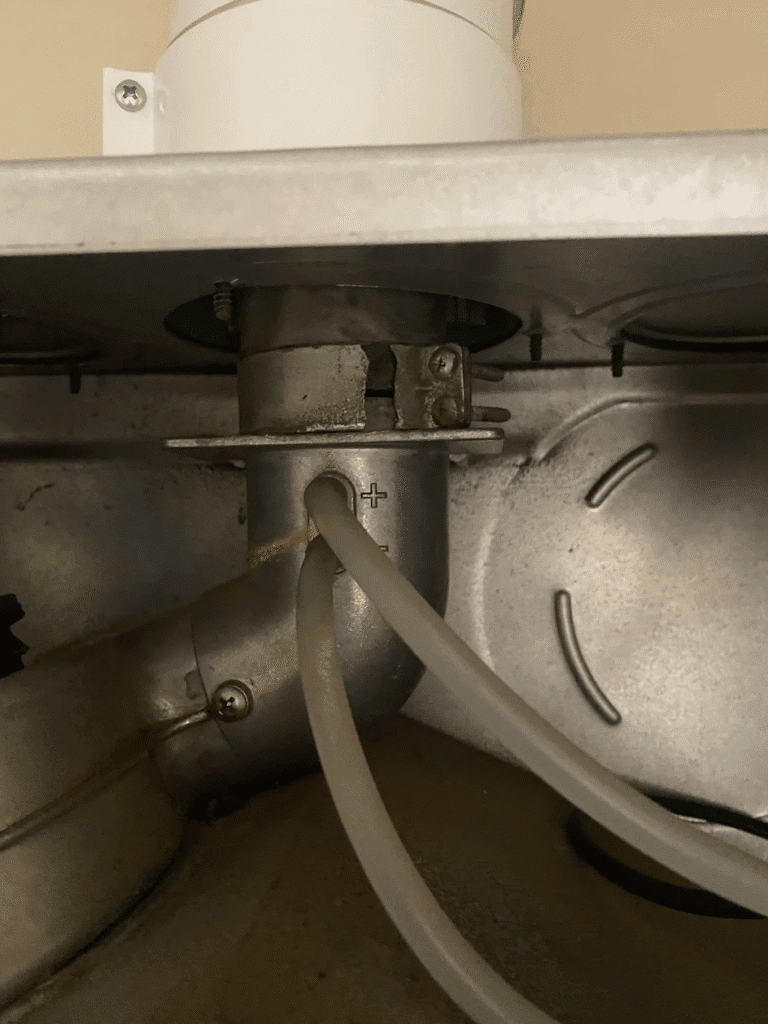

Locate your boiler’s filling loop – usually a braided metal hose with two isolation valves beneath the unit. Ensure your boiler is switched off and cooled down completely before beginning the repressurization process.

Slowly open both valves while watching the pressure gauge carefully – the pressure should rise gradually. Close both valves immediately when pressure reaches 1.5 bar to prevent over-pressurization. Turn your boiler back on and monitor for proper heating and warm water production.

If pressure drops repeatedly, you likely have a leak somewhere in your heating system that requires professional diagnosis by a Gas Safe engineer.

- Bleed the Radiators

Air trapped in your heating system prevents proper circulation, often making it appear that your boiler stops working when the issue involves radiator airlocks.

Why Air Traps Affect Heating

Air naturally accumulates in heating systems over time, creating pockets that prevent hot water from circulating effectively through radiators. These air traps cause cold spots in radiators, reduce overall system efficiency, and can trigger low water pressure conditions. When significant amounts of air enter the system, your boiler may struggle to maintain proper circulation, leading to overheating protection and automatic shutdown.

Step-by-Step Bleeding Process

Start with radiators furthest from your boiler and work systematically toward the unit itself. Turn off your heating system and allow radiators to cool completely before beginning. Use a radiator key or flat-head screwdriver to slowly open the bleed valve at the top corner of each radiator. Hold a container beneath the valve to catch escaping air and water. Close the valve immediately when steady water flow begins, indicating air removal. Check your pressure gauge after bleeding all radiators – you may need to add water to restore proper system pressure.

This systematic approach ensures optimal hot water circulation and can restore heating effectiveness when your boiler stops working due to air-related circulation problems.

- When DIY Fixes Don’t Work

Understanding the limitations of home troubleshooting prevents dangerous situations and costly damage when your boiler stops working due to complex internal problems.

Knowing the Limits of Home Troubleshooting

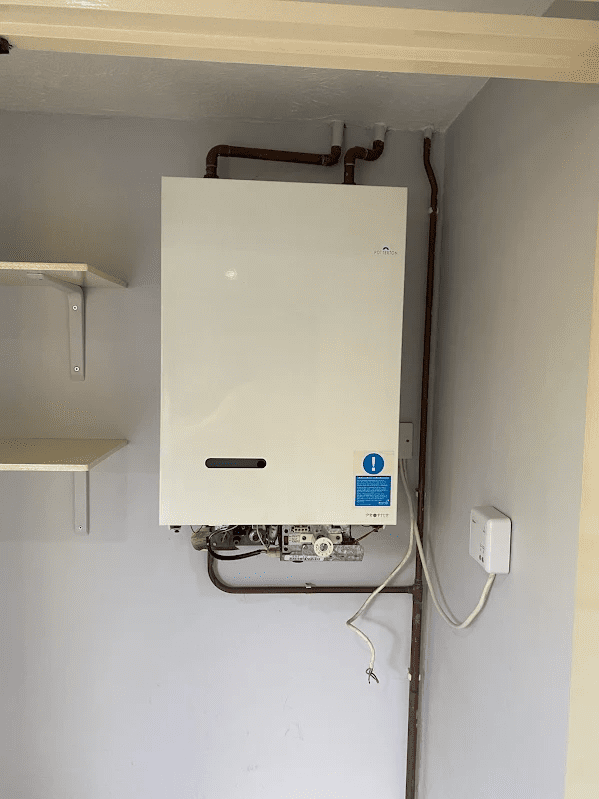

Issues involving gas safe components, heat exchanger problems, frozen condensate pipes, or persistent error codes require professional expertise from a Gas Safe registered engineer.

Internal component failures, unusual noises, or recurring problems after successful DIY fixes indicate underlying issues beyond homeowner capability. Boiler repairs involving gas connections, electrical wiring, or safety device adjustments must only be performed by qualified professionals to maintain safety and warranty coverage.

Avoiding Costly Mistakes

Attempting complex repairs yourself can void manufacturer warranties, create safety hazards, or cause additional damage requiring more expensive professional intervention. When basic troubleshooting steps fail to resolve the problem, continued DIY attempts often worsen the situation rather than providing solutions.

Professional diagnosis ensures accurate problem identification and appropriate repair strategies for long-term system reliability.

Conclusion

When your boiler stops working and basic troubleshooting steps don’t restore service, professional expertise becomes essential for safe, effective repairs and long-term system reliability.

At Pro Boiler Care Limited, we understand the frustration and inconvenience of unexpected heating system failures. Our Gas Safe-registered engineers provide 24/7 emergency response throughout Luton, Hitchin, and surrounding areas, ensuring you’re never left without heating and hot water when you need it most.

From simple pilot light issues to complex heat exchanger repairs, our team handles every aspect of boiler repairs with transparent pricing and guaranteed workmanship. We also provide comprehensive annual servicing to prevent future breakdowns and ensure your heating system operates safely and efficiently. Don’t let a malfunctioning boiler disrupt your daily routine – contact Pro Boiler Care Limited today for expert diagnosis and professional repair services you can trust.