When a heating problem boiler Luton families experience disrupts home comfort, quick identification and resolution prevent minor issues from becoming costly repairs. Luton’s variable weather patterns put additional strain on heating systems, making understanding common boiler problems essential for maintaining year-round warmth.

These practical solutions help restore reliable heating while recognizing when professional gas safe engineer intervention becomes necessary for safe, lasting repairs.

Common Heating Problems in Luton Homes

Luton properties frequently experience specific heating problems that affect comfort levels and energy efficiency throughout the year.

Uneven Heating Across Rooms

Different room temperatures throughout your home indicate circulation problems, preventing proper heat distribution. Radiators furthest from your boiler may remain cold while others heat normally, suggesting air trapped in the system or low water pressure affecting circulation.

To make sure that the uneven heating isn’t being caused by trapped air, check individual radiator valves to ensure they’re fully open and functioning correctly. Thermostatic radiator valves can malfunction, preventing proper temperature control in specific rooms.

Your smart thermostat may also need repositioning if it’s located in an area that doesn’t represent your home’s overall temperature accurately.

No Hot Water or Radiator Heat

Complete absence of hot water or heating indicates serious system malfunctions requiring immediate attention. Your boiler may display error codes, fail to respond to thermostat signals, or experience pilot light problems, preventing normal operation. Power supply interruptions, gas supply issues, or frozen condensate pipe conditions can trigger complete system shutdowns during colder periods.

To diagnose the issue, examine your boiler controls for warning lights or digital fault displays that indicate specific problems. The diverter valve may have failed, preventing proper switching between heating and hot water functions throughout your home.

Checking Boiler Pressure

Water pressure problems represent the most frequent heating problem boiler Luton technicians encounter during service calls throughout the year.

How Low or High Pressure Affects Heating

Your pressure gauge should read between 1.0 and 2.0 bars when the system is cold for optimal heating performance. Pressure below 1 bar prevents proper circulation, causing radiators to remain cold and reducing hot water availability. Excessive pressure above 3 bars triggers safety shutdowns and can damage internal components like the heat exchanger over time.

Simple Steps to Restore Balance

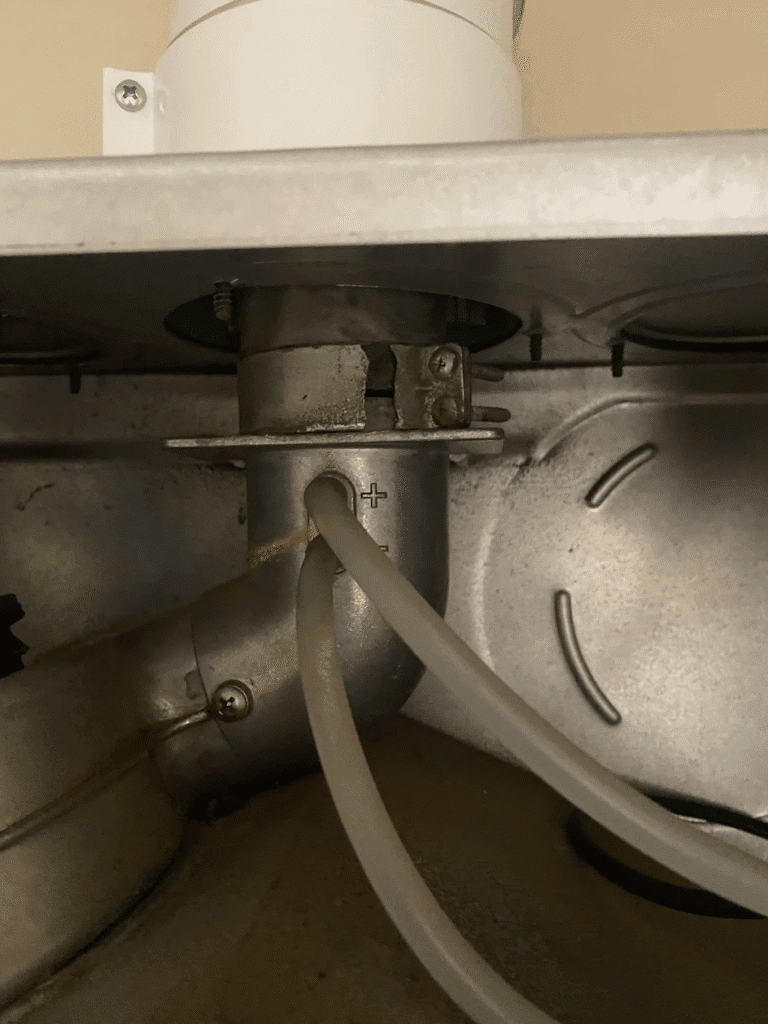

Locate your boiler’s filling loop beneath the unit and ensure the system is switched off completely before beginning. Open both valves slowly while monitoring the pressure gauge continuously until the pressure reaches 1.5 bars. Close valves immediately to prevent over-pressurization that could damage seals or gaskets.

Check that your fuse box hasn’t tripped during the process, as some systems include electrical safety interlocks. Test heating and hot water functions after repressurization to confirm proper system operation throughout your home.

If pressure drops repeatedly, contact a heating engineer for professional leak detection and repair services.

Bleeding Radiators

Air trapped in radiators creates common heating problems that reduce system efficiency and comfort levels throughout Luton homes.

Signs of Air Trapped in Radiators

Cold patches on radiator surfaces, particularly at the top, indicate air pockets preventing proper hot water circulation. Gurgling or bubbling noises from radiators during heating cycles suggest trapped air requiring bleeding procedures. Uneven temperatures between different radiators in the same room often result from air accumulation in the system.

Your heating system may take longer than normal to reach desired temperatures when air reduces circulation efficiency. Some radiators may remain completely cold while others heat properly, indicating significant air buildup requiring systematic bleeding.

Step-by-Step Bleeding Guide

Start with radiators furthest from your boiler and work systematically toward the unit itself for optimal results:

- Turn off your central heating system completely and allow radiators to cool for safety

- Use a radiator key to slowly open the bleed valve at each radiator’s top corner

- Hold a container beneath the valve to catch escaping air and water

- Close the valve immediately when a steady water flow begins, indicating air removal

- Check your pressure gauge after bleeding all radiators and add water if necessary

- Test your central heating system to confirm improved circulation and temperature distribution

This systematic approach ensures optimal warm water flow and can resolve many heating issues related to poor circulation.

Thermostat and Control Issues

Thermostat malfunctions often create the impression of serious heating failures when the actual issue involves control system settings or component failures.

Incorrect Settings Causing Heating Failures

Battery-powered thermostats stop communicating with boiler systems when batteries run low, preventing heating activation despite proper boiler function. Programming schedules on digital models may conflict with desired heating times, creating apparent system failures. Smart thermostat connectivity problems can interrupt heating cycles when Wi-Fi connections become unstable.

How to Reset or Replace Thermostats

Replace thermostat batteries and verify temperature settings exceed room temperature by 2-3 degrees minimum. Reset digital programmers by following manufacturer instructions, typically involving specific button combinations held for prescribed durations. Reconnect smart thermostat systems to your home’s Wi-Fi network if connectivity issues prevent proper operation.

Professional heating engineers can diagnose complex control problems involving internal wiring, communication failures, or compatibility issues between different system components.

Strange Boiler Noises

Unusual sounds from your central heating system often indicate developing boiler issues requiring prompt attention to prevent costly component damage.

Identifying Whistling, Banging, or Kettling Sounds

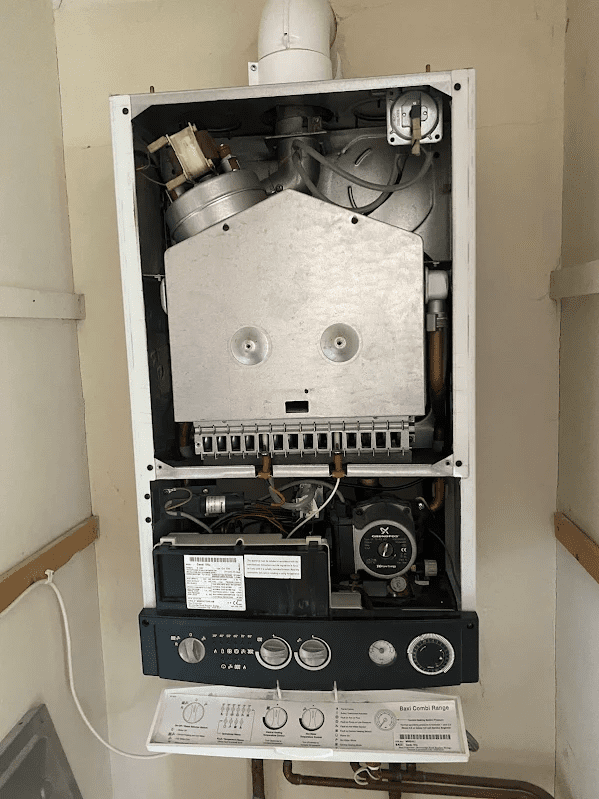

Kettling sounds like a boiling kettle and indicates limescale buildup on heat exchanger surfaces, reducing efficiency and potentially causing permanent damage. Banging noises suggest pump problems, loose components, or rapid temperature changes, causing thermal expansion. Whistling sounds typically indicate restricted airflow, blocked flues, or damaged internal seals affecting combustion.

What These Noises Mean and Quick Fixes

Kettling requires professional system flushing to remove limescale deposits and restore proper heat transfer efficiency. Banging noises may resolve through pump speed adjustments or bleeding air from the system.

Persistent unusual sounds indicate internal component wear requiring professional assessment by Gas Safe-registered engineers.

When Professional Help Is Needed

Recognizing situations requiring professional intervention prevents dangerous DIY attempts and ensures proper resolution of complex heating problem boiler issues.

Warning Signs of Serious Problems

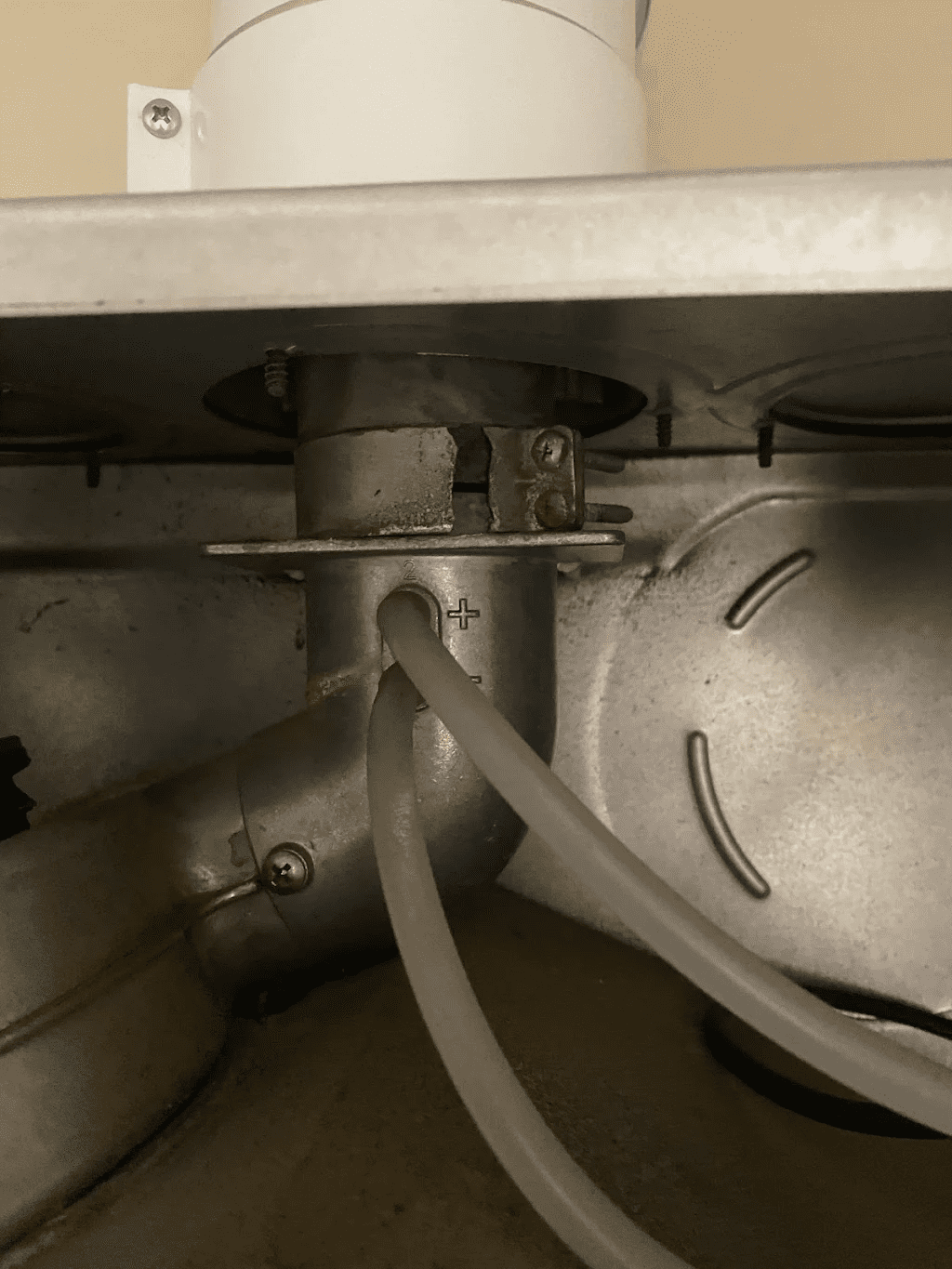

Gas odors around your boiler indicate potentially dangerous leaks requiring immediate evacuation and emergency gas services. Persistent error codes after successful boiler reset attempts suggest internal component failures beyond homeowner capability. Visible water leaks, especially near the heat exchanger or pressure relief valve, indicate serious problems requiring professional assessment.

Carbon monoxide exposure symptoms like headaches, dizziness, or nausea require immediate professional intervention and household evacuation. Repeated system failures despite successful troubleshooting attempts indicate underlying issues requiring expert diagnosis.

Why Luton Families Should Call Certified Engineers

Gas safe registered engineers possess specialized training, proper insurance coverage, and legal authority to work safely on gas appliances. Professional diagnosis prevents misidentification of problems that could worsen through inappropriate DIY repairs. Emergency services provide 24/7 availability when heating failures occur during weekends, holidays, or overnight periods.

Qualified engineers carry specialized tools, replacement parts, and safety equipment necessary for complex boiler repairs. Professional work maintains manufacturer warranties and ensures compliance with safety regulations while preventing recurring failures.

Attempting complex repairs yourself risks personal safety and can void insurance coverage or warranty protection for your heating system.

Conclusion

While basic troubleshooting resolves many boiler issues, professional expertise ensures safe, lasting solutions for your home’s comfort needs.

At Pro Boiler Care Limited, we understand how frustrating heating problems can be for Luton families, especially during the coldest months. Our gas safe registered engineers provide comprehensive boiler repairs and emergency services throughout Luton and surrounding areas, ensuring reliable warmth when you need it most.

Don’t let heating issues leave your home cold. Contact Pro Boiler Care Limited today for expert diagnosis and professional repair services that keep Luton families warm and comfortable year-round.