When an emergency boiler breakdown strikes unexpectedly, knowing how to respond quickly and safely protects your family while minimizing damage to your heating system. Sudden boiler failures often occur during the coldest months when your home depends most on reliable heating and hot water.

In this guide, you will understand the essential steps to take during an emergency. This detailed guide ensures that you can act decisively while waiting for professional assistance from a gas safe engineer.

Recognizing an Emergency Breakdown

An emergency boiler breakdown requires immediate attention when your heating system poses safety risks or completely fails to provide essential services to your home.

Complete Loss of Heating or Hot Water

Total heating failure during winter conditions constitutes an emergency, especially when temperatures drop below freezing and vulnerable household members need warmth.

Your boiler may display persistent error codes, refuse to respond to boiler reset attempts, or fail to ignite despite having adequate power supply and gas availability. Complete loss of hot water affects daily hygiene, cooking, and cleaning activities essential for household function.

Unusual Smells, Noises, or Leaks

Gas odors around your heating system indicate potentially dangerous leaks requiring immediate evacuation and emergency gas services. Unusual metallic banging, continuous gurgling, or high-pitched whistling sounds suggest internal component failures that could worsen rapidly.

Water leaks around the boiler, especially near the heat exchanger or pressure relief valve, can cause significant property damage and indicate serious system pressure problems.

These warning signs often precede complete system failures and should never be ignored or dismissed as minor inconveniences.

Immediate Safety Steps

Taking proper safety measures during an emergency boiler breakdown protects your family from potential hazards while preserving your heating system from further damage.

Turning Off Gas, Electricity, and Water Supply

As a first step, locate your gas meter’s emergency shut-off valve and turn it clockwise to stop gas flow to your property immediately if you smell gas or suspect leaks. Switch off electrical power to your boiler at the fuse box or circuit breaker to prevent electrical hazards during system malfunctions. Turn off your home’s main water supply if you notice significant leaks that could cause flooding or water damage.

Ensuring Household Safety

Open windows and doors to ventilate areas where you suspect gas leaks, but avoid using electrical switches or creating sparks that could ignite accumulated gas.

Evacuate all household members and pets if you detect strong gas odors or signs of carbon monoxide exposure like headaches, dizziness, or nausea. Move to a safe location away from your property before calling emergency services or gas safety hotlines.

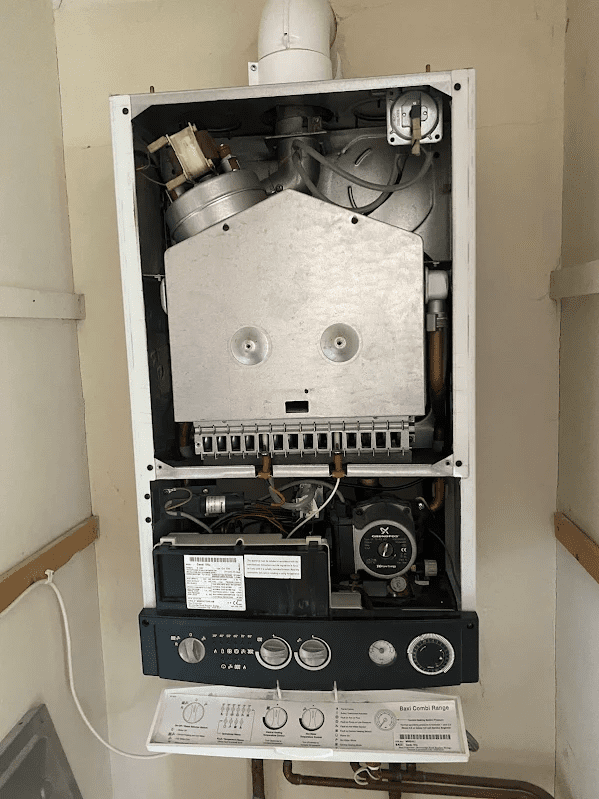

Common Causes of Sudden Boiler Failure

Understanding typical causes of emergency boiler breakdown helps identify potential solutions and communicates effectively with professional repair services when they arrive.

Pressure Loss

Sudden pressure drops often trigger automatic safety shutdowns in modern boilers, preventing operation until pressure restoration. Major leaks in heating pipework, radiator connections, or internal boiler components can cause rapid pressure loss requiring immediate professional attention. Faulty pressure relief valves may discharge water unnecessarily, creating artificial pressure drops that appear as emergency breakdowns

Frozen Pipes

Frozen condensate pipes represent common winter emergency causes, blocking drainage systems and triggering automatic boiler shutdowns. External condensate pipes freeze when temperatures drop below freezing, preventing proper boiler operation until thawing occurs. Internal pipework freezing can cause pipe bursts, water damage, and complete heating system failures requiring extensive repairs.

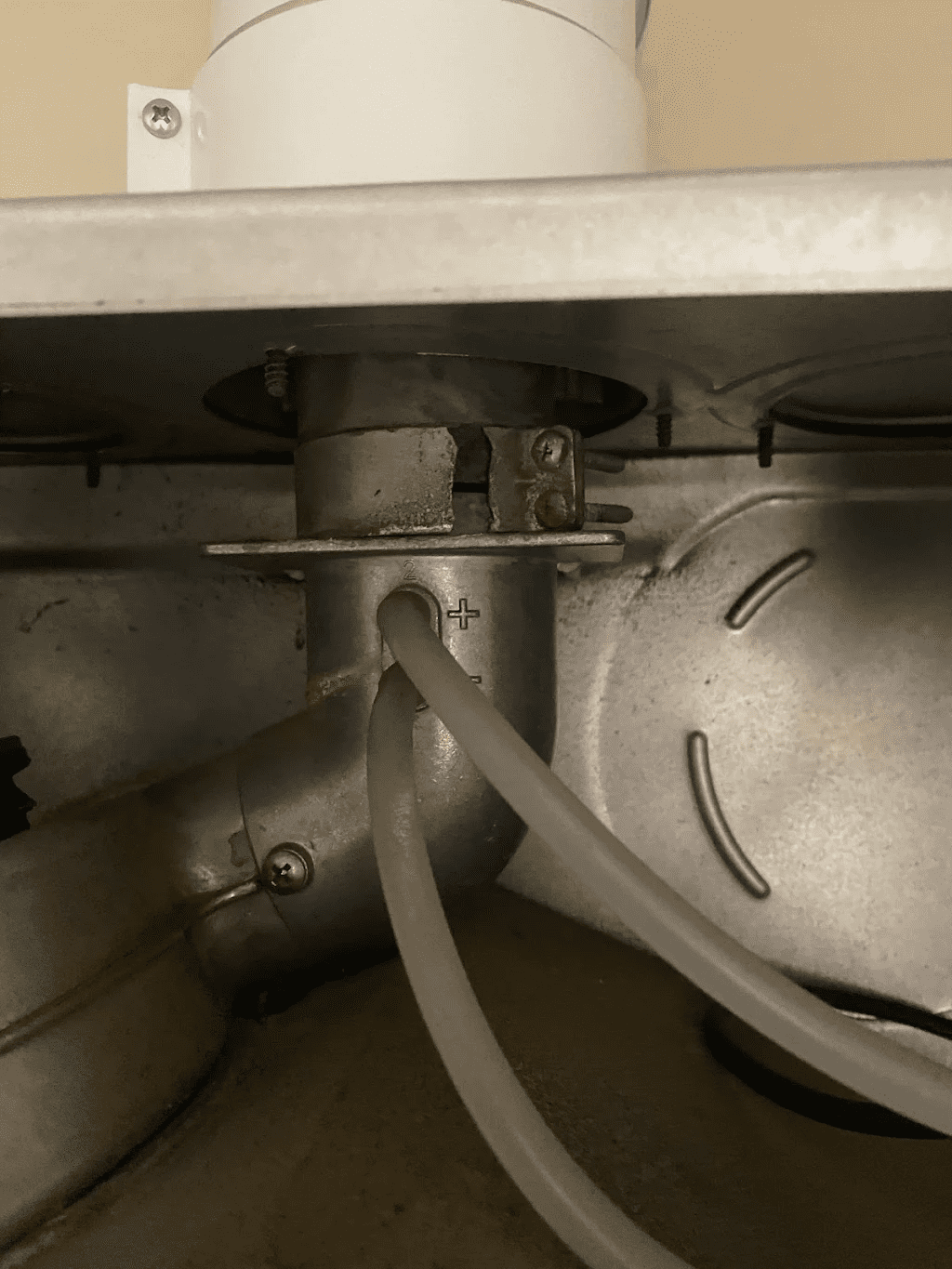

Ignition or Pilot Light Issues

Pilot light failures prevent proper boiler ignition, leaving your home without heating or hot water during critical periods. Electronic ignition systems can malfunction due to electrical faults, gas supply interruptions, or internal component failures requiring professional diagnosis. Repeated ignition failures often indicate underlying problems with gas pressure, air supply, or safety device malfunctions that pose potential safety risks.

Quick Checks Before Calling an Engineer

Performing systematic checks during an emergency boiler breakdown can sometimes restore basic operation while determining whether professional intervention is immediately necessary.

Resetting the Boiler

Locate your boiler’s reset button and press it firmly for several seconds, then wait at least five minutes before attempting a system restart. Verify that your power supply remains stable by checking that other electrical appliances work normally throughout your home. Examine error codes displayed on boiler controls and note specific numbers or symbols to report accurately to professional engineers.

Checking Thermostat and Controls

Verify thermostat batteries and replace them if digital displays appear dim or unresponsive during emergency situations. Ensure temperature settings exceed current room temperature by at least 3-4 degrees to trigger heating activation. Check programming schedules on smart thermostat systems – some emergency situations coincide with automatic setback periods that appear as system failures.

Examine all heating controls for proper positioning, ensuring the diverter valve allows heating operation and that manual override switches haven’t been accidentally activated.

Inspecting Pressure and Radiators

Monitor your pressure gauge for readings below 1.0 bar that might explain heating failures during emergency situations. Feel radiators for residual warmth that might indicate partial system operation or recent heating activity before complete failure occurred. Check individual radiator valves to ensure they remain open and haven’t been accidentally closed during routine maintenance.

These preliminary checks help determine whether simple adjustments might restore temporary operation while professional help travels to your location.

When to Call a Professional Engineer

Recognizing situations requiring immediate professional intervention prevents dangerous DIY attempts during emergency boiler breakdown scenarios and ensures proper safety protocols.

Signs the Issue Is Beyond DIY

Persistent gas odors, unusual noises from internal components, or visible damage to the heat exchanger require immediate professional assessment by qualified engineers. Repeated system failures after successful reset attempts indicate complex internal problems beyond homeowner capability. Water pressure problems involving continuous pressure loss, despite repressurization attempts, suggest major leaks requiring professional diagnosis and repair.

Electrical faults affecting boiler operation, especially those involving repeated circuit breaker trips or power supply interruptions, require expert electrical assessment for safe resolution.

Importance of Gas Safe Registered Engineers

Gas safe registered engineers possess specialized training, insurance coverage, and legal authority to work safely on gas appliances during emergency situations. Professional diagnosis prevents misidentification of problems that could worsen through inappropriate DIY interventions. Emergency repair services provide 24/7 availability when heating failures occur during weekends, holidays, or overnight periods.

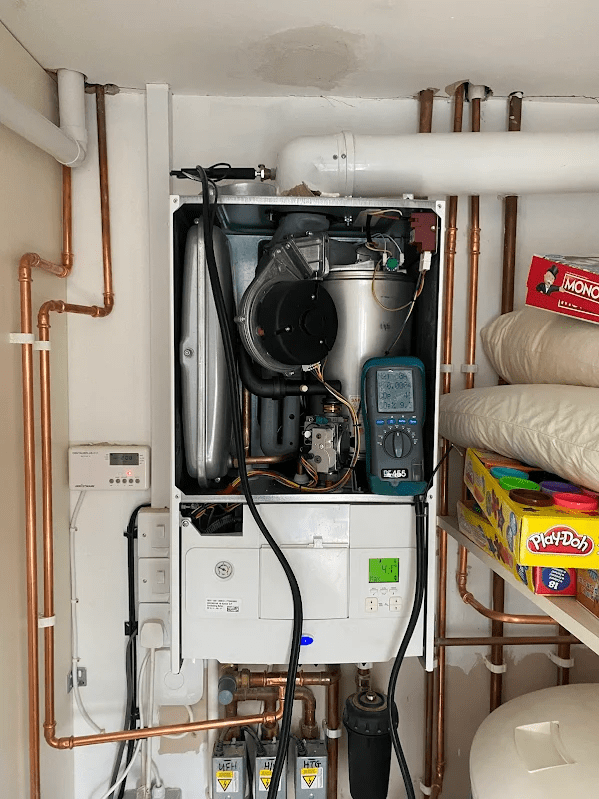

Qualified engineers carry specialized tools, replacement parts, and safety equipment necessary for emergency boiler repairs that restore reliable operation and prevent recurring failures.

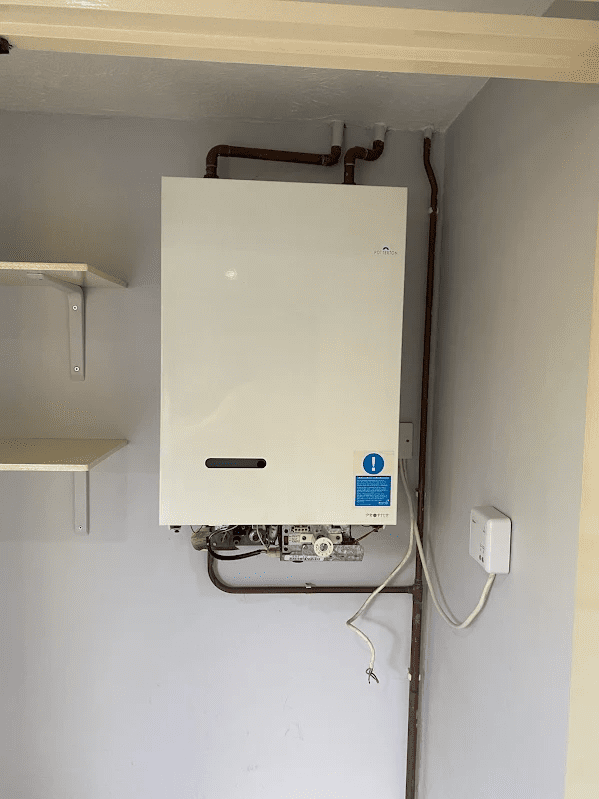

Preventing Future Emergencies

Proactive maintenance and seasonal preparation significantly reduce the likelihood of emergency boiler breakdown situations while extending your heating system’s operational lifespan.

Regular Servicing and Maintenance

Annual professional servicing identifies developing problems before they cause emergency failures, ensuring reliable operation during peak winter heating demand. Gas safe engineers inspect internal components, test safety devices, and clean essential parts that homeowners cannot safely access. Professional maintenance includes checking the condensate pipe, examining gas connections, and verifying proper combustion for optimal efficiency and safety.

Regular servicing maintains manufacturer warranties and ensures compliance with safety regulations while preventing costly emergency repair situations that disrupt household routines.

Seasonal Checks Before Winter

Test your heating system during autumn months before cold weather creates emergency situations, allowing time for non-urgent repairs and maintenance. Inspect external condensate pipes for proper insulation and drainage to prevent frozen condensate pipe problems during winter freezes. Check that radiator valves operate smoothly and bleed air from the system to ensure optimal warm water circulation throughout your home.

Verify adequate heating fuel supplies, functioning thermostats, and clear ventilation around your boiler area before increased winter heating demands begin.

Conclusion

While basic troubleshooting helps during emergency boiler breakdown situations, professional expertise ensures safe resolution and long-term system reliability for your home.

At Pro Boiler Care Limited, we understand that heating emergencies never happen at convenient times. Our gas safe registered engineers provide 24/7 emergency response throughout Hitchin, Luton, and surrounding areas, ensuring you’re never left without heating when you need it most.

Don’t face your next heating emergency alone. Contact Pro Boiler Care Limited for immediate professional assistance and peace of mind you can trust.